U-Tube Manometer FAQ

Radon system U-Tube manometers. What are they? How do they work? We answer all of the frequently asked questions about these devices here!

U-Tube Manometer FAQs

We get a lot of questions about u-tube manometers from clients. So we wanted to create a list of the most common questions that we receive and give answers to explain the details about what these meters are doing - and what they do not do.

Q: What is it?

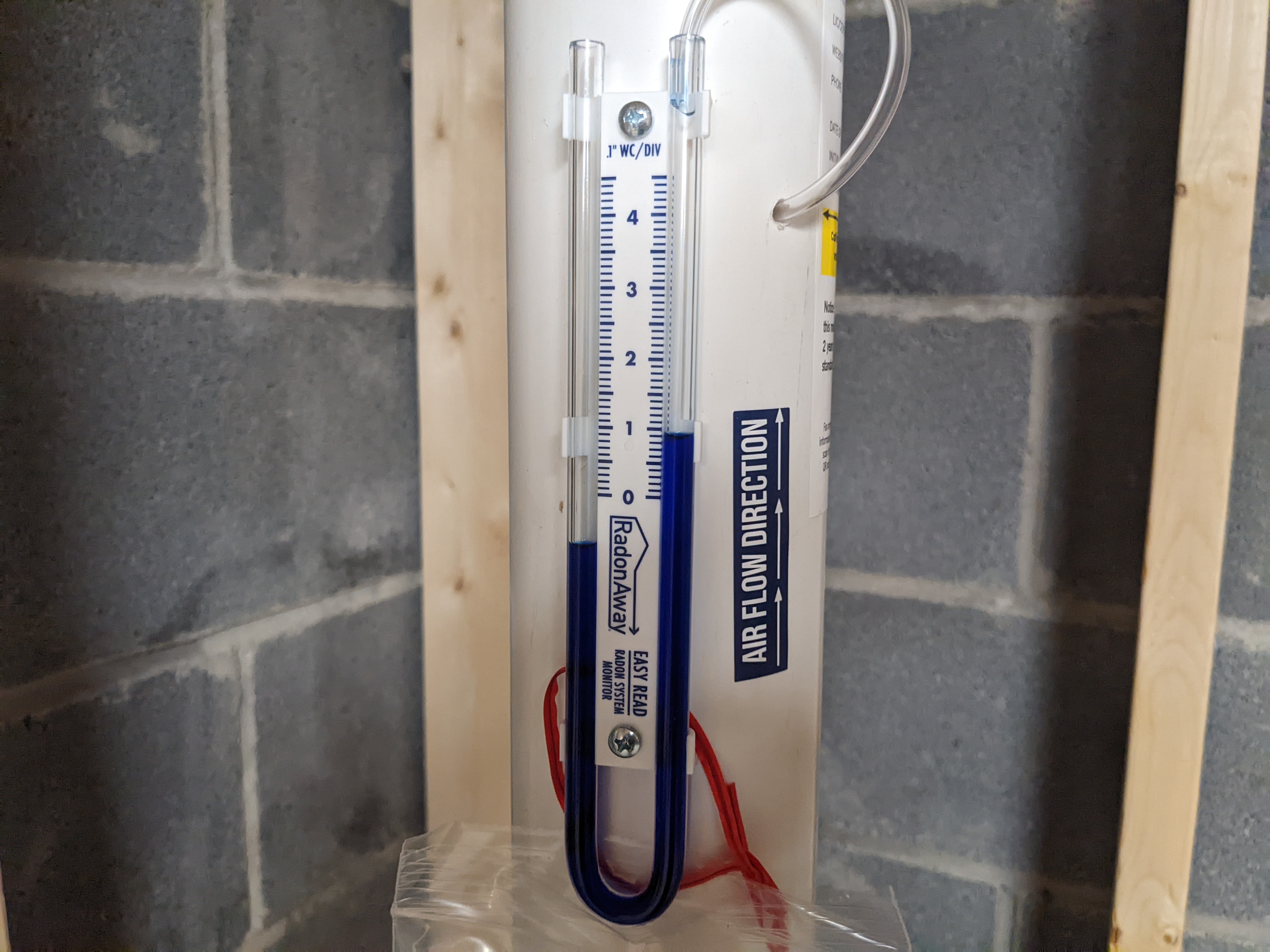

A: The U-Tube manometer is a devices that shows the amount of suction occurring within the system. This is represented through a water column. It helps installers and homeowners to quickly determine if the system is operating.

Q: What does the reading mean?

A: Mainly, it shows if there is suction within the piping - or if there is none at all. It also helps installers know how much suction and restriction is occurring in the system. The desired amount of restriction will be different depending on the certain conditions (what fan is used, how much restriction is below the soil, how well openings in the slab are sealed, etc.).

Q: Do the meters tell you what the radon level is?

A: No. It will not give any information regarding radon levels within the home or system. It is only showing if there is suction within the piping.

Q: What is the “ideal reading”?

A: The ideal reading will be different for every system. The fan manufacturer will give details about the CFM (air flow), static pressure, and power consumption for the specific fan that is installed. Based on the reading from the manometer, the installer can determine the details on how the system will perform. Each fan will have a recommended maximum operating pressure. This is typically below 2.2 inches for most standard-sized fans.

Q: Is the system working better if the liquid is higher?

A: If the liquid is extremely offset (high on one side, low on the other - over 3 inches on the water column), that is not a good sign. That typically indicates that there is a lot of restriction within the system - in other words, the fan is not pulling a lot of air (and radon) out of the ground. Because the system is restricted, the liquid will be sucked higher into the manometer, causing an excessive offset on one side.

*This is a broad statement and should not be considered as an absolute determination about a specific system or design.

Q: What is the liquid?

A: Most manometers will be filled with dyed oil - typically red or blue.

Q: Does the liquid (oil) freeze?

A: The oil likely will not freeze, but the consistency may get thicker.

Q: Can the manometer be installed outdoors?

A: Yes. Although if it is exposed to direct sunlight it could cause the plastic to deteriorate at a faster rate than normal. AARST standards state that monitors should be protected from damage and degradation.

Q: Is a manometer required on a mitigation system?

A: AARST standards require a monitoring mechanism to directly indicate if the fan, blowers, or other integral mechanical components are operating within the established operating range. This can be achieved with a manometer pressure gauge or electrical amperage gauge. So technically speaking, a manometer is not required to be installed; however, the system should be equipped with a monitoring device - and the manometer pressure gauge is the most practical option for that requirement.

Q: Where should the manometer be installed?

A: AARST standards require monitoring devices (such as the manometer) “to be located where it is readily seen and protected from damage or degradation.” We should also state that the manometer should be located on the suction side of the piping (BEFORE the fan) - not on the pressure side (AFTER the fan).